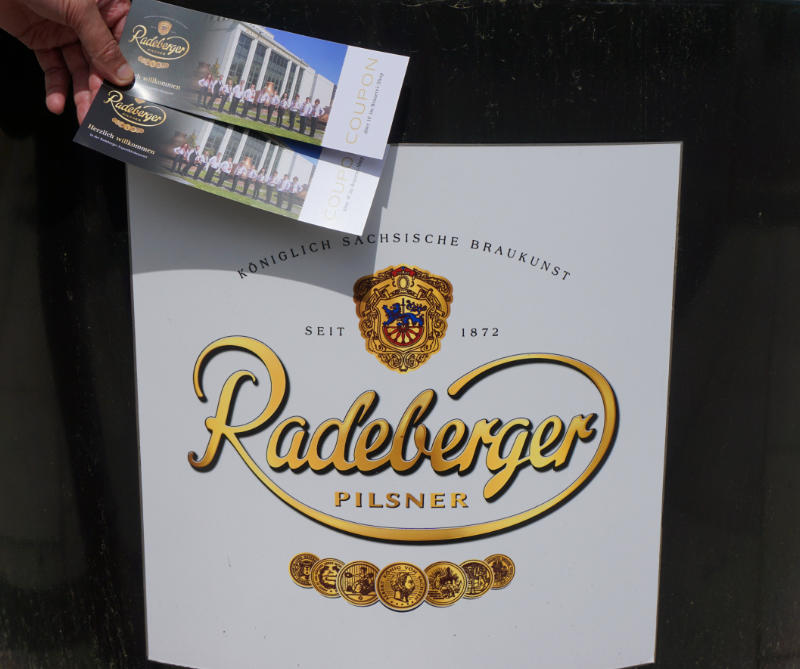

A trip to Radeberg and a visit to the brewery just belong together. As part of our research trip to Radeberg, we, too, visited the Export Beer Brewery Radeberg.

A brief history of the brewery

Five men who all didn’t know the first thing about beer founded a brewery based on shares in Radeberg in 1872 and called it “Zum Bergkeller” (Mountain Vault). They were inspired by a new beer from Bohemia, a pilsner that was one of its kind in the region.

The founders set out to achieve their declared goal: To brew an even better beer.

They founded a company called Radeberger Exportbrauerei (Export Beer Brewery Radeberg). The excellent reputation of the pilsner from Radebrg travelled around the region quickly. The people of the town Pilsen also got wind of it. Brewery business people were not exactly thrilled about this new beer. They were of the opinion that only beer from Pilsen should be allowed to carry the name pilsner and sued the company in 1910. They were unsuccessful with their case, however, and the court ruled that the word “Radeberger” in the name discloses the origin of the beer sufficiently and that “pilsner” describes a kind of beer and not a regional origin.

That pilsner has been the only beer brewed in Radeberg right from the start. The hop and malt used to be sourced from Bohemia. The water has always been from Karlswald (Karls Forest) in Radeberg and it is to this day. It is a lot softer than water from other sources and it makes the taste of the beer so distinctive. Karlswald is only 7 kilometres from the brewery. Very early on subterranean pipes were successfully used to transport the water from its source directly to the plant.

In December 1905 a decree gave the beer the title “official beverage of His Royal Majesty King Friedrich August of Saxony”. Soon after, His Royal Majesty even visited the brewery. His crest is still printed on every bottle of Radeberger.

Production was scaled up over time so that the brewery inevitably developed into a large, industrial endeavour. The development of a cooling machine by a man called von Linde and the improvement of the drying kiln by a brewer from Radeberg were essential factors in the history of growth of the brewery.

By the end of the 19th century the beer was already exported to New York and a little later it was sold internationally. Today, the Export Beer Brewery Radeberg ships their product to 87 countries on all continents.

During the time of the GDR, the beer was mainly produced for export. In Germany itself, it was sold, for example, in Interhotels (a newly founded GDR luxury hotel chain).

After the German Reunification, the brewery was refurbished and expanded once more. New machines were installed and today its brewing technology and equipment is cutting edge. Distribution is organised via wholesalers. Up to 120 lorries owned by different companies arrive at the brewery daily to pick up beer.

Radeberger export beer brewery – a guided tour

Our guided tour of the Export Beer Brewery Radeberg begins in the brewhouse with a little bit of history. After the prologue, we get to see the brewery. We visited on a bank holiday which meant that all production had been stopped for the day and visitors were free to walk through the halls, stop and take everything in. Of course, we followed the rules that prohibit photographic within the brewery even though we really would have liked to take some pictures for the blog post.

The input about the brewing process was very informative and eloquently presented. We were told that the Export Beer Brewery Radeberg has a capacity of 18 brews per day which is the equivalent of 10500 hectolitres. They need around 10.000 kilogram malt per brew. 42 tanks of different sizes for fermentation are held in the cellar of the building. The biggest one holds the equivalent of a maximum of 30.000 cases.

These enormous production volumes surprised me and to be completely honest, I had difficulties picturing what these numbers actually meant. But broken down into bottles these 30.00 cases make up 360.000 bottles (given that one case holds 12 0.5 litre bottles). If I drink one bottle every day I would need 989 years to empty one of the fermentation tanks if my math is correct. Cheers.

We also saw the cutting edge filling system. Too bad that all machines were stopped. These ones I would have loved to see in operation. One of the filling plants fills around 50.000 bottles per hour. Every bottle takes around one hour to be processed and placed in a case – from entering the machine to completion of the filling process. The bottles that the Brewery in Radeberg uses are unique and are reused up to nine times. They carry a special embossing that can be read by the machines. Other bottles by different companies are pulled out by the machines. That is why visitors can find cases with empty bottles that aren’t the Radeberg Brewery ones on the premises.

The tour ends in a conference room. Fresh Pilsner was already waiting for us which we got to enjoy after a toast.

I was pleased to find out that we would get to drink the Radeberger Zwickelbier next. This is the unfiltered version of the Pilsner that can’t be kept in bottles because of its very short shelf life. I almost like it better than the Pilsner.

At the very end, we received a little present – we got to take our beer glasses home with us. Thanks a lot!

This wasn’t our first tour through a brewery – and certainly not the last! – but I still find it interesting. The tech behind it and the art of brewing are very fascinating to me. The tasting at the end of the tour lets me discover new flavours and I am happy that beer can be so diverse!

Leave a Reply