The subject of porcelain has fascinated mankind for many years. Meissen is famous for its beautiful and exquisite Meissen porcelain, so a visit to the Staatliche Porzellan-Manufaktur Meissen GmbH is simply part of a visit to the city.

How did the porcelain come to Meissen?

At the beginning of the 18th century, the alchemist Johann Friedrich Böttger tried to produce gold in countless experiments. When the Saxon Elector Augustus the Strong found out about this, he had Böttger locked up in the Jungfernbastei. There he was to produce gold only for him. The attempts failed again and again. It took some time until Ehrenfried Walther von Tschirnhaus was able to convince Böttger to switch to the production of white gold, i.e. porcelain. In the European princely courts, porcelain was already considered a highly sought-after commodity in the 13th century, and it could only be imported from China at inflated prices. Böttger began experimenting at the end of September 1707.

It did not take long and after Böttger had produced marbled tiles and the red Böttger stoneware (jasper porcelain), he succeeded in producing European porcelain, much to the delight of Augustus the Strong.

The Elector patented the manufacturing process in 1710 and tried to keep it secret. Porcelain was very precious and sought after at that time. By decree of 23.1.1710, he founded the “Royal Polish and Electoral Saxon Porcelain Manufactory”.

From March 1710, the porcelain production facilities moved step by step to Albrechtsburg Castle in Meissen. Here, the “recipe” for porcelain was further refined and it was hoped that the secret of production could be kept secret. Only a small circle of employees knew the secret of porcelain production. However, one employee managed to steal the secret. He fled to Vienna and there, with the help of his knowledge, a competing product was created in 1718.

An additional reason why Meissen was chosen as a production site was the possibility of extracting raw materials. There are kaolin mines in the region, which provide one of the raw materials needed for porcelain production.

Soon, the first smooth vessels were created, onglaze colours developed and decorative elements could be painted onto the porcelain. Around 1740, Chinese and Japanese décors began to be replaced by German décors with flowers. The onion pattern in underglaze blue, which is still known today, came onto the market.

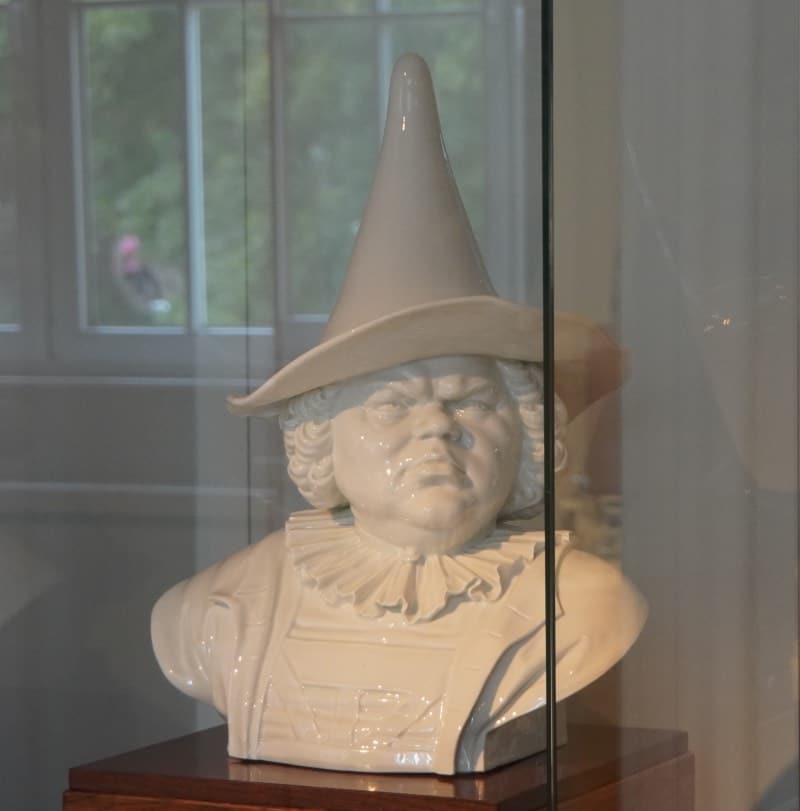

In addition, the production of figurative sculpture for representative and decorative purposes developed. The large white animal figures created by Johann Gottlieb Kirchner until 1731 became particularly well-known.

The development of Meissen porcelain from the mid-19th century onwards

At the beginning of the 19th century, the Meissen manufactory had great sales difficulties. The royal houses had to save due to increased expenditure during the war and existing debts, and the citizens could not and did not want to buy the porcelain. The type of production did not meet the taste of the time. At times, the manufactory was in such a bad financial situation that it even considered giving up production. The state intervened and placed the company under the control of the Saxon Ministry of Finance.

The new director of the manufactory, Carl Wilhelm von Oppel, finally succeeded in implementing artistic, technical and commercial changes. Thus, from the middle of the 19th century, under the influence of the Dresden Academy of Art, the so-called “Academy Porcelain” was created, which was very popular. In addition, parts of the production were moved from Albrechtsburg Castle to a new production facility in Meißen Triebischtal. The production site of the white gold is still located there today.

In the second half of the 19th century, the company was able to record growth again. The princely houses wanted to emphasise their positions again and so ordered traditional Meissen decorative and tableware porcelains in the formal language of the Baroque and Rococo periods. Artistically, however, this was a step backwards; traditional decorations were desired and hardly any new creations were in demand. Nevertheless, individual pieces were made especially for trade fairs and exhibitions that deviated from the “usual”.

After the First World War, with new management and new artists, the figurative area continued to inspire and found interested buyers worldwide. In the 1920s-1930s, many simple and beautifully shaped pieces were also created in the tableware sector, which were enthusiastically received. The first porcelain chime, which hangs in the Meissen Frauenkirche, was also created at this time.

Development after the Second World War

In mid-1945, the Soviet military administration dismantled parts of the production plant. Nevertheless, work was resumed and Meissen porcelain was presented at the first post-war trade fair in Leipzig at the beginning of 1946.

After some restructuring, the manufactory became a state-owned enterprise and was given the name “VEB Staatliche Porzellan-Manufaktur Meißen”. A new department was created that designed and produced murals from Meissen porcelain. During the GDR period, the manufactory became the eighth strongest foreign exchange earner and soon only produced mass-produced goods. At the same time, attention was also paid to producing pieces that were as contemporary as possible and that appealed to people in terms of form and décor.

After the political change, the manufactory rebranded itself. The production programme now included contemporary figurines, vessels and tableware (still classic models of the 18th century, tableware with onglaze decorations and classic as well as newly designed onion pattern decorations). For many years the economic situation was very tense, numerous employees lost their jobs and finished goods were even destroyed in order to contribute to safeguarding the value of Meissen porcelain…

In 2014, the Free State of Saxony founded the Meissner Porzellan-Stiftung GmbH, which now owns all the model moulds, recipes and museum objects. Today, there is an approximate stock of 700,000 different moulds and around 10,000 of the foundation’s own colour formulations to fall back on. The moulds are made available to the Meissner Porzellanmanufaktur in return for payment.

At the moment, the manufactory is trying to find its way back from luxury products to porcelain with more affordable series. Historical and new decorations are to be used.

How do you recognise Meissen porcelain?

As competition increased, it was realised that Meissen porcelain should be marked to confirm its authenticity. Thus, a manufactory mark was developed.

The Saxon electoral swords formed the model for the blue crossed swords, which have been applied by hand since 1720. By 1730, letters had been added to the swords:

K.P.M. for “Königliche Porzellan-Manufaktur”,

M.P.M. for “Meissen Porcelain Manufactory”,

K.P.F. for “Königliche Porzellan-Fabrik”.

From 1731, following a written order from the Electoral Court in Dresden, there was only the sword figurative mark.

Despite all the uniformity, so-called marks are still added today. Each turner, moulder and embosser adds his own mark (embossed or incised mark, his own number) and thus makes the porcelain unique. In addition, each painter who artistically designs the piece adds his or her own mark (own number) to the glaze.

Visit to the exhibition workshop in Meissen

Since 2006, there has been a modern visitor centre in Meissen. The show workshop and the company museum are located here. We took a very interesting tour of the show workshop and learned a lot about the production of Meissen porcelain.

The turner

The visit to the show workshop begins with the turner. On a potter’s wheel driven by the foot, we were shown how a cup is shaped.

Prefabricated mould blanks are also used, into which the porcelain mass is filled. The mould is made of plaster and thus slowly removes the water from the porcelain mass, thus compacting the mass. After a short curing period, the mould is removed and the cup handle is attached. The cup then has to dry for several days before it is fired at 950 degrees for the first time.

The turner also showed us how figures are made. Here, too, prefabricated moulds are used. This is used to make a part of the whole figure, because each figure always consists of several individual elements that are later joined together to form a whole.

The Embosser

In the next room, we were introduced to the work of an embosser, a job title I had never heard of before. It is the job of the embosser to put together the individual parts of an object. He uses the so-called slip, a porcelain mass of a certain consistency. This acts like a “glue” and joins the individual parts of figures together, for example.

The embosser also makes small decorative elements, such as leaves or flowers, by hand or with a stencil and attaches them to the objects. Each embosser has his or her own design language, which makes each object unique. In the case of elaborate objects, the process can take up to six months.

The painting

In the third room, a painter from the field of underglaze painting was working. After an object has been fired for the first time, it can be painted under the glaze.

There are only a few shades that can be used in this area, as many do not withstand the second firing. The cobalt blue used by the porcelain manufactory is particularly popular. This colour is used not only for the Meissen swords but also for the famous onion pattern.

The special thing about underglaze inks is that they fuse with the blank during firing, making the product tamper-proof.

The on-glaze painting

The tour ended with a visit to a glaze painter. Her job is to paint patterns onto the glaze of the porcelain.

After the pattern has been sketched out with a pencil, one colour after the other is applied. The special shades are mixed from colour pigments and turpentine according to special recipes.

After application, each shade dries for several hours. So each onglaze painter always works on several pieces at the same time and, as each has his own talent, each also has his own area, such as flowers or animals. Once the product is finished, it goes into the decorative firing and is then sold.

Visit to the Meissen Porcelain Museum

After our guided tour of the show workshop, we were able to visit the large and impressive museum at our leisure. A tour that impressed me very much.

On display is porcelain that has been produced in Meissen from 1710 to the present day. From cups to huge figurative images, from white to colourful, there is an incredible amount to discover here.

I found the porcelain clocks and the first organ with porcelain pipes particularly interesting. At certain times, these are also played, so that you can directly hear the difference between wooden, metal and porcelain pipes. It took many years to make the pipes. It was not until the year 2000 that they were satisfied with the result.

I was impressed by the figurative representations. Some were small and so intricately crafted that you were afraid they would break just by looking at them. Other figures were huge and richly detailed, and must have taken a long time to make.

I would not have associated the field of technical porcelain, for example for fittings or apothecary vessels, with Meissner Porcelain and so I was very surprised to find that the manufactory also produces these works.

Address:

Staatliche Porzellan-Manufaktur Meissen GmbH

Erlebniswelt HAUS MEISSEN®

Talstraße 9

01662 Meißen

Deutschland

Public car park of the Meißen public utility company:

Talstraße 10 (200m from the main entrance)

Opening hours:

January, February

Monday – Sunday: 9am – 4pm

March-December

Monday – Sunday: 9am – 5pm

31.12. and 01.01.: 10 – 16h

24, 25 and 26.12. closed

MEISSEN Café:

Monday – Sunday

daily: 11am – 4pm

31.12. and 1.1.: 11 – 16h

Closing days: 24, 25 and 26.12.

Admission fees:

Adults: 12 EUR

The entrance fee includes an audio guide tour of the show workshop, bookable in 14 languages, and an individual visit to the Meissen Porcelain Foundation Museum.

Public guided tours in the show workshop (approx. 40 min.)

May – October

daily every hour, between 10.00 a.m. and 2.00 p.m.

Adults: € 17.00

The visit to the show workshop and the museum was made possible by the STAATLICHE PORZELLAN-MANUFAKTUR MEISSEN GMBH. Many thanks!

Leave a Reply